Blood Oxygenator

Spectrum Medical’s Extracorporeal Membrane Ventilation Technology is another world first technology combining a revolutionary fluid path design.

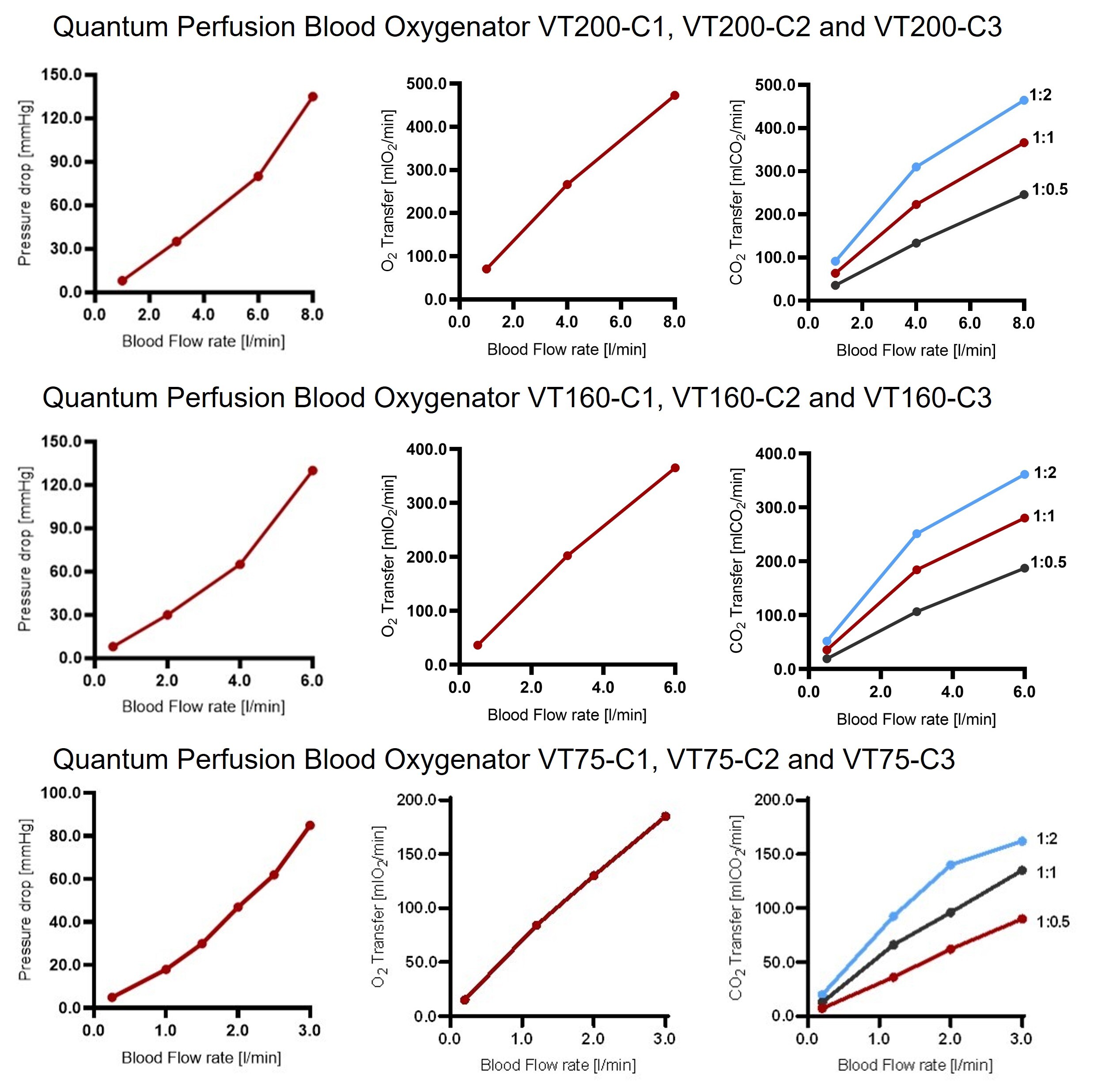

Sizes available:

- Large Adult - Poly-Propylene (PP) and Ply-Methylepentene (PMP) membrane options available

- Small Adult - Poly-Propylene (PP) and Ply-Methylepentene (PMP) membrane options available

Total Surface Area (Ventilation Efficiency)

Spectrum Medical’s revolutionary laminated membrane construction significantly increases gas exchange efficiency, minimises pressure drop and priming volume. The unique construction eliminates the current compromise between fibre bundle compression and low priming volume. Individually all fibre layers within the fibre bundle are separated by ten microns, leading to a significant advantage in that the individual fibres within the laminated bundle construction, are in contact with flowing patient blood and providing gas exchange. This significant increases in gas transfer efficiency leads to a reduction in blood contact surface area and by default a lower priming volume and pressure drop.

Superior Air Handling

Spectrum Medical continues its commitment to patient safety with the integration of its patented Quantum Vortex Flow technology. This innovation in fluid dynamics ensures that blood flow passing through the laminated bundle construction is centrifugal in nature which generates a fluid vortex to support the separation of gross air from flowing patient blood. This separation of gross air from patient blood ensures almost instantaneous priming in addition to minimising or eliminating venous air being passed through to the arterial circuit.

Air handling is further supported with a 40 micron arterial filter integrated into the fibre bundle to eliminate the need for additional priming volume.

Maximum Fluid Dynamic Performance

The elimination of low velocity sections and dead space within the fluid path has been at the forefront of Spectrum Medical’s “anti-thrombotic” strategy. This unique design concept in conjunction with the Quantum Vortex Flow and Fibre Separation technologies guarantees that the total surface area of the laminated bundle construction is subjected to a circulating blood flow with a guaranteed full volume wash out of approximately 4 seconds when flowing blood at 5 lpm.

Biocompatibility

Resulting from significant process research, a world first in the application of PC1036 crosslinked biocompatibility coating to a fibre membrane construction. Superior adhesion qualities, elasticity and surface smoothness maximises antithrombotic performance throughout the life of the product.

Materials free from DEHP

Commitment is again emphasised with all internal blood contacting surfaces being made from materials free from plasticizers.